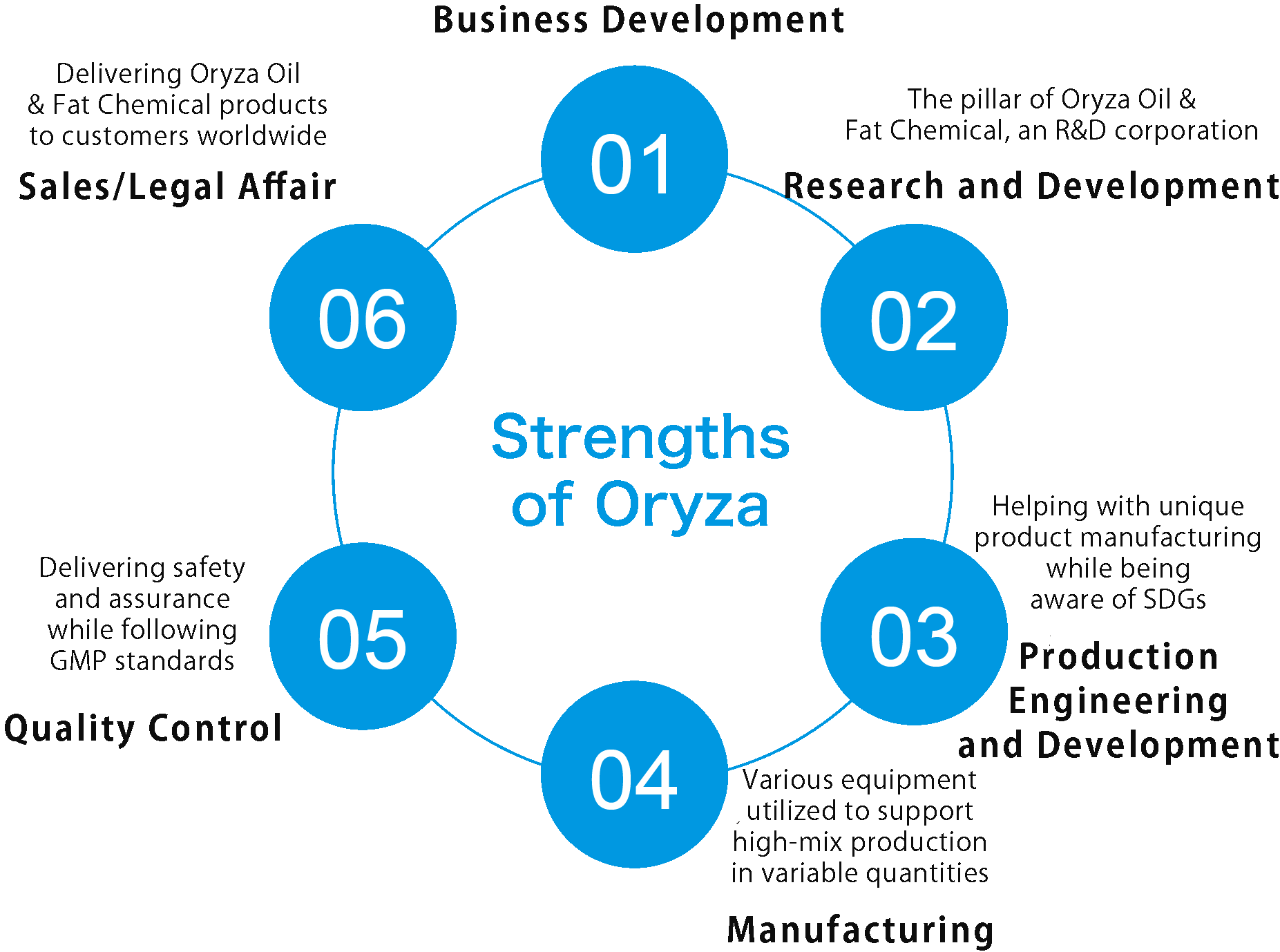

Oryza’s Strengths

- TOP

- Oryza’s Strengths

![]()

Business Development

We develop our businesses with unconventional and free ideas born from the fusion of nature and science.

Oryza Oil & Fat Chemical Co., Ltd.

Head Office: Aichi Prefecture/Sales Office: Tokyo Prefecture

Oryza Oil & Fat Chemical established in 1939 as Gifu Rice Bran Oil Plant.

Oryza was the first in

the Chubu region to establish mass production techniques, beginning with the production and sale of

rice bran oil made from rice bran and rice germ, which are byproducts of polishing brown rice. In

1976, we successfully developed the world's first low-temperature extraction method (NEM) for rice

bran oil, and in 1982, we obtained a global patent. This enabled the extraction and refinement of

higher-quality, better-tasting rice bran oil.

Oryza Oil & Fat Chemical, which started its

business with the production of rice bran oil, focuses on the health components abundantly found in

rice bran. Alongside entering the functional ingredients business, we established a new research and

development department. In addition to rice bran and rice germ, we have aimed to make effective use

of numerous underutilized resources worldwide and have developed expertise in extracting

health-promoting components from various natural raw materials. Our research and development, which

applies the natural forces of "activation and inhibition", is at a world-class level.

![]()

Research and Development

A global network has also been constructed by our research and

development efforts.

Through research and development in pursuit of truth, we have turned

manny impossibilities into possibilities.

When we talk about "contributing to health", there are many areas that this encompasses.

From

the standpoint of preventive medicine and anti-aging, we have paved our way into not only the Japan

market but the global market, developing unique products in a niche that meets niche and unique

products.

Utilizing over 2,000 assay systems we have accumulated to date, we build evidence focusing on

bioactivity.

We release the truth, proven through in vitro, in vivo, and clinical tests. These

research findings are presented at various conferences and posted in papers both nationally and

internationally.

Speed in product development is also one of our strengths. While it typically takes 3 to 5 years to

bring a creative new product to market, we achieve this within a one-year timeframe.

New

product development meetings are attended not only by the R&D department but also various members of

Sales, Production Engineering and development, and Manufacturing, who gather and discuss the new

products.

Each employee's ideas are promptly considered without missing opportunities. If there

is a possibility, we will quickly turn it into action with a “Try First & Fast” mentality. This is

perhaps the reason Oryza Oil & Fat Chemical is able to continually output new products brimming with

creativity.

Over 2,000 Assay*

Patterns Held

*An assay is a method to quantitatively assess or measure the quantity, functional activity, or response of samples.

![]()

Patent Applications

| Japan Patents Obtained |

316 |

|---|---|

| Japan Patents Obtained |

85 |

| Japan Patents Obtained |

34 |

| International Patents Obtained |

20 |

![]()

Number of Postings in Papers

Postings in

Highly Authoritative Academic Journals

| In Japan |

15 |

|---|---|

| Overseas |

72 |

| Postings in Professional Journals |

223 |

Functional Food and Cosmetic Material Business>

Note: Track record as of June 2025

![]()

Production Technology Development

We utilize our many years of experience and know-how to not only

produce original products, but to provide a one-stop service from investigating contracted product

quality improvements, cost-down, and lab tests for new projects to actually launching

production.

Another one of Oryza’s strengths is that we can support a wide range of extraction and

fractionation of water-soluble components, fat-soluble components, and other components through our

experience using rich variations of organic solvents and our knowledge of extraction.

With a

customer first motto, we create processing systems to satisfy you on every level and help you create a

customized one-of-a-kind product.

Start the contract processing business

About34years of experience

Accumulated track record of handling Ingredients

In-house manufactured products

Client companies in the contract processing business

300 companies

Inquiries per year

![]()

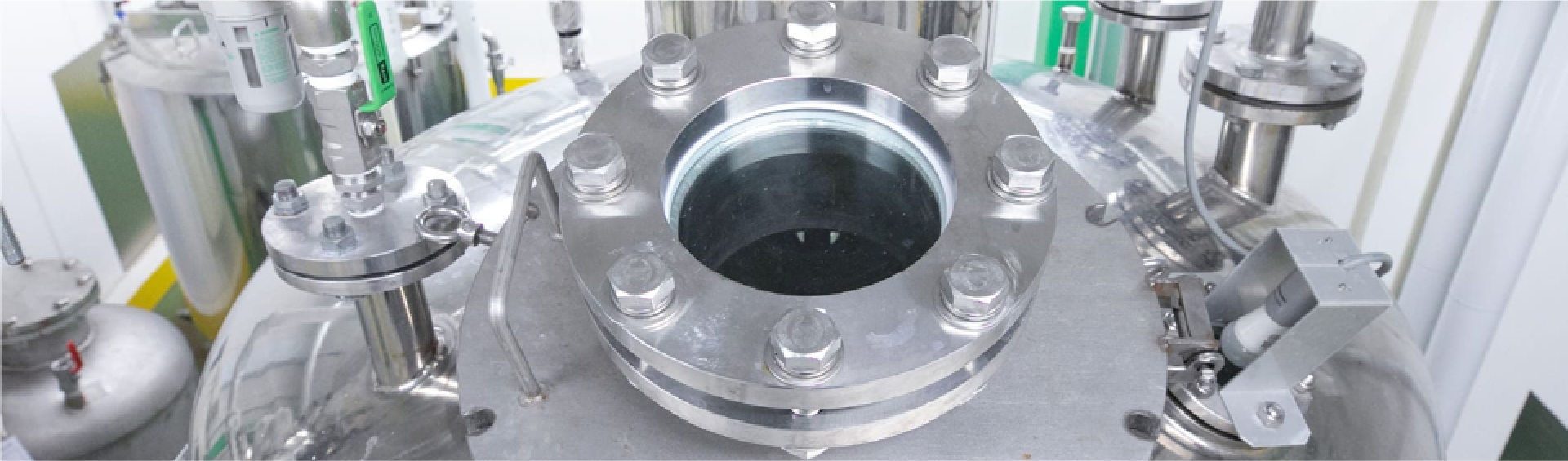

Manufacturing

We use a variety of solvents and equipment to extract, refine, and fractionate grams to tons of oil and fat ingredients and grams to hundreds of kilograms of functional food and cosmetic ingredients. We possess various devices to support high-mix production in variable quantities in order to meet the personalized needs of our customers on a daily basis.

Our production line consists of large, medium, and small extruders, reactors, and concentrators/distillers as well as column separators, allowing us to handle any type of processing.

![]()

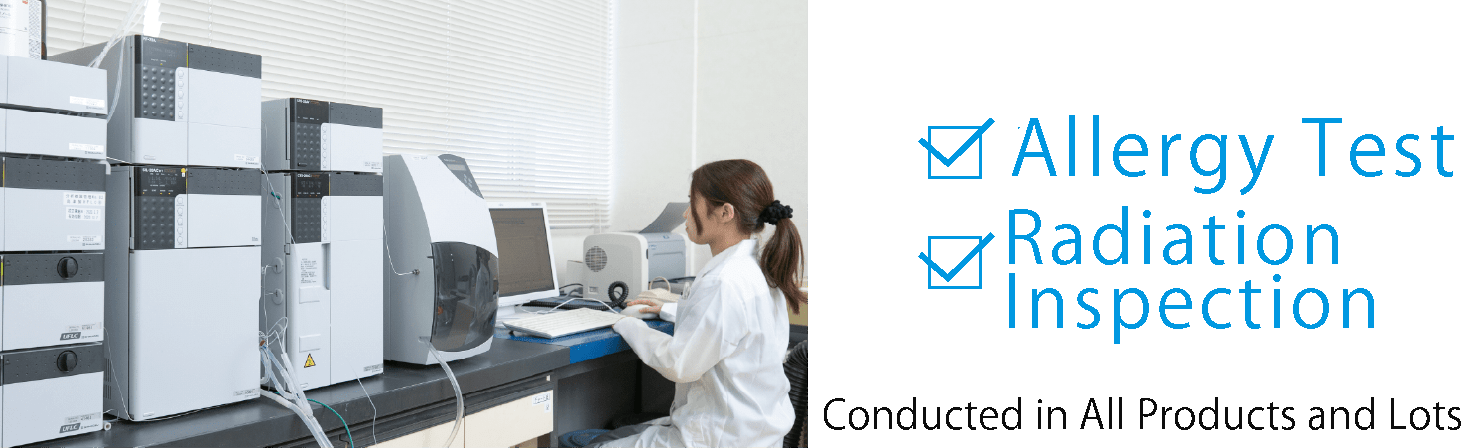

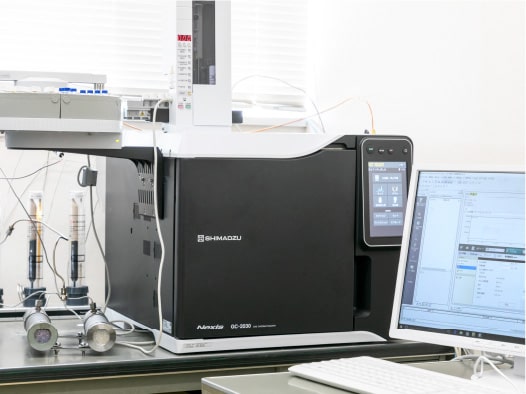

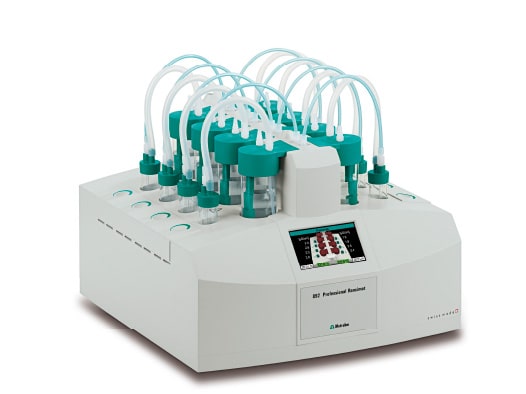

Quality Control

Oryza Oil & Fat Chemical’s quality control system follows GMP standards, monitoring the quality

standards of the entire process from raw material receiving, to intermediates, through to the final

product, guaranteeing the perfect quality.

We perform product manufacturing while following the

manufacturing operation standard set forth by GMP, and we have established traceability through

product test results and manufacturing control logs. Using the analysis results of the established

quality standards as a basis, we stringently determine whether to accept or refuse deliveries of raw

material and whether or not to ship products.

Amid growing concerns about food safety, we

utilize a range of analytical equipment, including HPLC, GC, GCMS, UV, and NIR. Additionally, we

have invested in a number of advanced devices. For instance, we recently added Flash GC Nose

instruments for the chemical analysis of aromas and CDM instruments for measuring the oxidative

stability of oils and fats. With safety as our top priority, we also perform comprehensive analyses

of all functional components and active substances used in products like foods and

cosmetics.

We also conduct radiation inspections and allergy testing for the seven specified

allergens across all products and production lots.

Over 2,000 Assay*

Patterns Held

*An assay is a method to quantitatively assess or measure the quantity, functional activity, or response of samples.

Oryza Oil & Fat Chemical’s Analysis Equipment

-

HPLC (High Performance Liquid Chromatography)

Main Use: To Analyze Functional Components Quantitatively

-

GC (Gas Chromatography)

Main Uses: To Analyze the Fatty Acid Composition in Oil and Fat Products

To Analyze Functional Components Quantitatively -

GCMS (Gas Chromatograph-Mass Spectrometer)

Main Use: To Analyze Residual Solvents

-

UV (Ultraviolet and Visible Spectrophotometer)

Main Uses: To Measure the Oryzanol Content

To Measure the Polyphenol Content -

NIR (Near Infrared Analyzer)

Main Uses: To Measure the Amount of Oil and Water and the Acid Value of Bran

To Measure the Acid Value of Crude Oil -

Flash GC Nose (Aroma Analyzer)

Main Use: To Analyze Aromatic Components

-

CDM (Oxidation Stability Test Equipment)

Main Use: To Test Oils and Fats’ Stability Against Oxidation

![]()

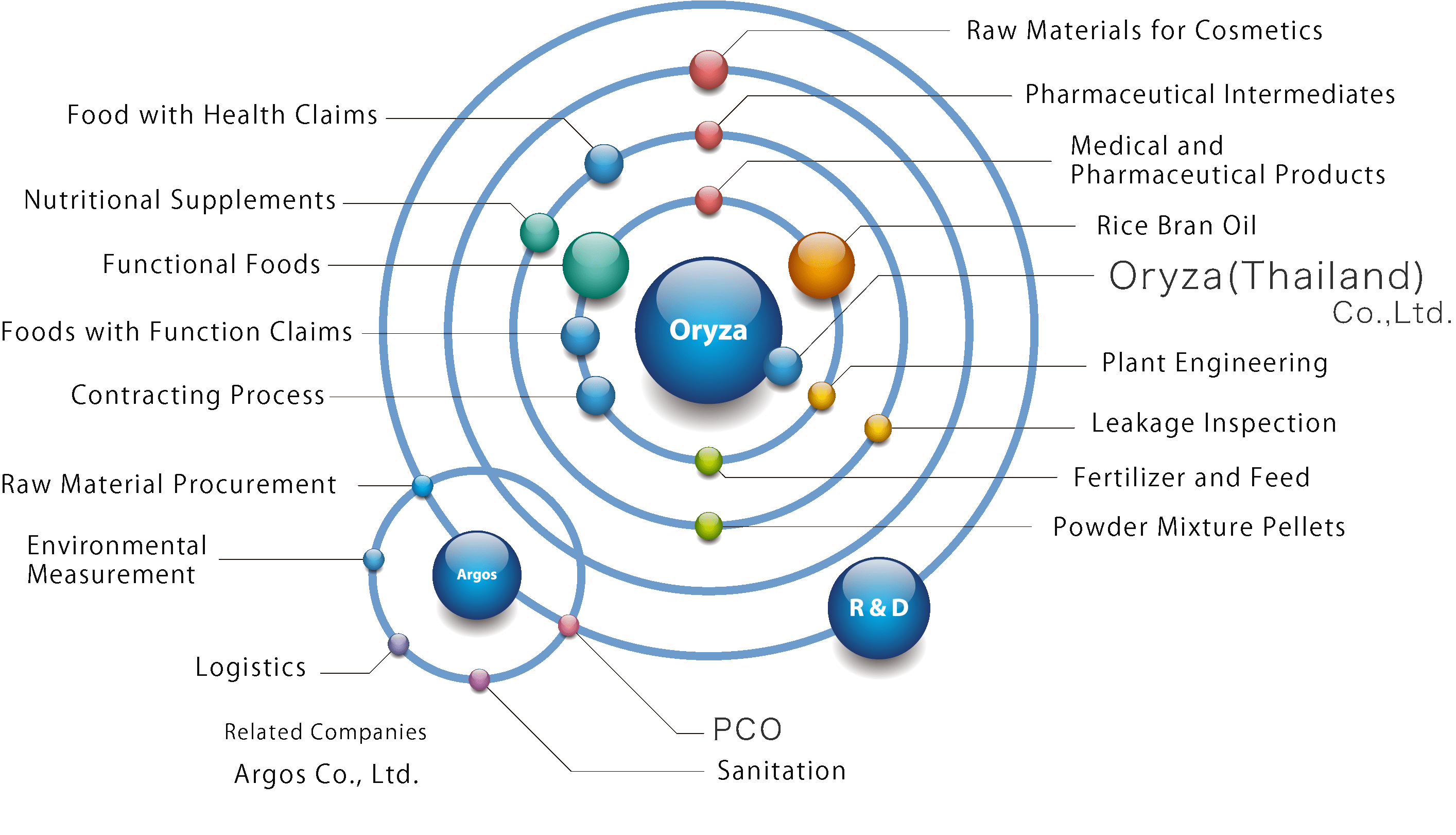

Food, functional food, medical and pharmaceutical products, Ingredients for cosmetics, and rice bran oilーa product we have been consistently making for over 80 years since inception... We at Oryza Oil & Fat Chemical are specialists in a wide variety of fields, helping to make products that satisfy customers all over the world.

Oryza Oil & Fat Chemical’s Products

51countries

We proactively share information and give presentations on new products, regularly participating in trade shows in Japan and around the world, as well as sharing updates through webinars.

Around 25 years ago, in preparation for global expansion, we began upgrading our product catalogs, presentation materials, and other documentation into English and Chinese, and started entering overseas markets. In 2017, we established a local subsidiary, ORYZA THAILAND, and openned a representative office in Malaysia. As a result, we are now working with over 2,000 companies within Japan and more than 510 companies across 51 countries worldwide.

▶Click here for an introduction to Oryza (Thailand) Co., Ltd.

Moreover, we are safeguard our rights appropriately by obtaining patents worldwide and registering

trademarks for branding the products we have developed. We enable our customers worldwide to fully

benefit from this intellectual property.

The global network Oryza Oil & Fat Chemical has built

one of our greatest trengths

Patents & Registered Trademarks

- Domestic patent

-

Patent Applications

316Patent Applications

85

- International patent

-

International Patents Obtained

34Japan Registered Trademarks

20

- Registered trademark

-

Japan Registered Trademarks

66Overseas Registered Trademarks

33

Note: Track record as of June 2025

Oryza Oil & Fat Chemical is committed to pursuing global challenges through corporate activities aligned with the SDGs.

Oryza Oil & Fat Chemical’s SDGs Declaration >

Contact us with any questions or comments about our products.

Head Office:

Head Office:

+81-586-86-5141

Tokyo Sales Office:

+81-3-5209-9150

Reception Hours:

9:00 a.m.–5:00 p.m.

Monday–Friday

(excluding weekends and holidays)