Do you have any specific needs or concerns when selecting a contract manufacturing company?

"It is possible to manufacture Ingredients for health food and cosmetics. We support the extraction and refinement of fats and extracts using various organic solvents."

We provide comprehensive support from product design and manufacturing to functionality assessments and market development for food and cosmetic ingredient production.

Our Strengths in ODM/OEM

*INCI: International Nomenclature for Cosmetic Ingredients

Oryza Oil & Fat Chemical in Numbers:

(Contract Processing Version)

Note: Track record as of June 2025

Started the contract processing business

1991

About 34 years of experience

Cumulative Experience in Handling Ingredients

More than

300

kinds

In-house

More than

80

kinds

More than

200

products

Clients in the Contract Manufacturing Business

Approx

300

companies

Inquiries per year

More than

100

Patent Applications

316

Japan Patents Obtained

85

International Patents Applications

34

International Patents Obtained

20

Fields We

Excel In / Frequently Received Requests

Fields We

Excel In / Frequently Received Requests

Fields We Excel In

Ingredients for Food Products

(Ingredients for Functional Foods and General Food Products)

Ingredients for Cosmetics

Ingredients for Medical and Pharmaceutical Products

Ingredients for Quasi-Drugs

We also handle many other fields.

Oryza’s

Equipment

Oryza’s

Equipment Licenses

and Certifications

Licenses

and Certifications

Examples of Frequently Received Requests

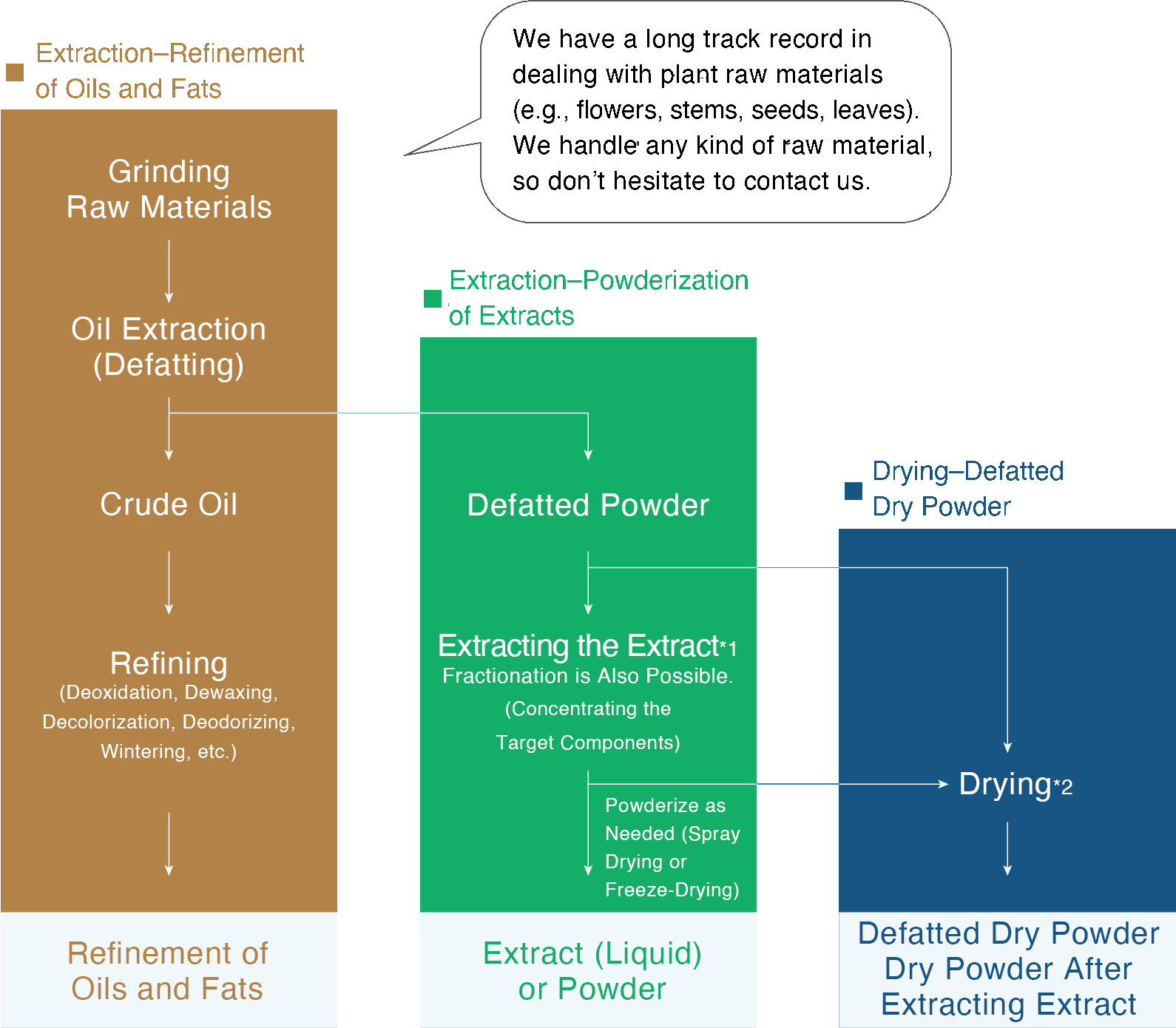

※1 Extraction solvents: can be reused.

※2 Extracted and Dried

Powder: Potential for Effective Utilization.

We assist in creating products in the form you desire, starting from your preferred raw materials, and offering services such as oil and fat extraction, extraction processing, and powderization.

Contract

Service Flow

Contract

Service Flow

-

Your requests

- ・Contact us via phone, e-mail, or our website inquiry forms.

-

Consultation

Proposals/ Planning One to two months

-

・We can meet directly or use internet tools (Zoom, Teams, etc.).

・Let us know the product shape/form, throughput, delivery date, and expenses you have in mind.☆Feel free to consult us about design, process flow, specifications, and distribution channels. With our extensive expertise and network built over many years, we will provide you with the best possible solutions.

・We enter into nondisclosure agreements before or after meeting with you.

-

Lab Test Run

One to two months

-

・We conduct a test run at the lab scale.

・Repeat test runs are possible depending on the purpose.

・You assess the prototype and make the final decision regarding the specifications. -

Actual Manufacturing

-

・You may be present during manufacturing.

・Consult us on the product packaging. -

Quality Analysis From two–three months to your desired delivery

date.

-

・We are also able to issue various analyses and test reports.

- Follow-Up

-

・Leave post-manufacturing and delivery support to us.

・Discuss various application support and market introductions with us.

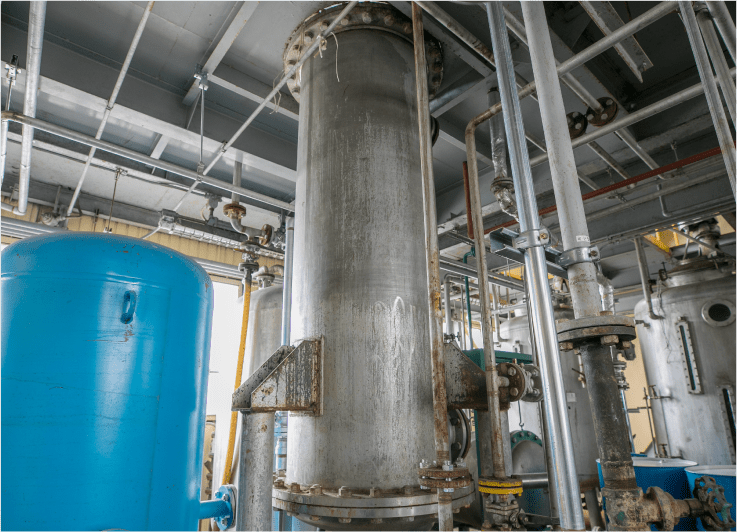

Equipment

Equipment

-

Sugar Mill

We can also use other grinding equipment, such as power mills, hammer mills, and pin mills.

Grinding

Sugar Mill

-

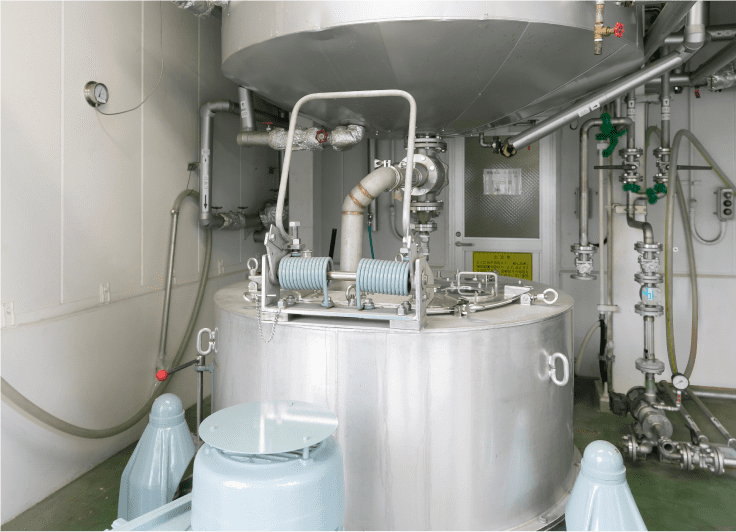

Reaction Kettle with Agitator (SUS, GL)

Comes with Jacket

(Temperature can be controlled. [e.g., cooling, warming])

Scale: 200–10,000 LExtraction

Concentrating Kiln with Agitator

-

Basket-Type Centrifugal Separator

We also possess other solid-liquid separation equipment, such as a filter-press and sparkler filter.

Solid-Liquid Separation

Basket-Type Centrifugal Separator

-

Concentrating Kiln with Agitator (SUS)

Scale: 500 L, 50 L x 2 (for laboratory)

Fractionation

Column

-

Concentrating Kiln with Agitator (SUS)

Comes with Jacket (can be temperature controlled with cooling, warming, etc.)

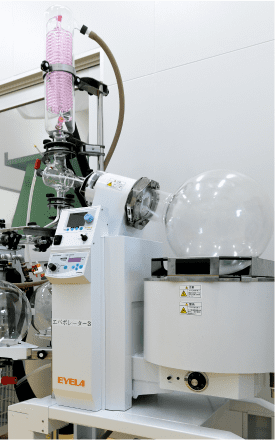

Scale: 200–3,000 L

We also have a 10 L rotary evaporator that can be used for trial runs.

Concentration

Concentrating Kiln with Agitator

-

Spray Dryer

Water Evaporation Amount: 25 kg/hr

Drying Powder Amount: Approx. 5 kg/hrPowderization

Spray Dryer

-

フリーズドライヤー

Coagulation Amount: 80 kg/Batch

Drying Powder Amount: Approx. 24 kg/BatchPowderization

Freeze Dryer

-

V Blender

Scale: 100 L (equipment capacity)

Mixing

V Blender

-

Sieving Machine

Mesh Sizes We Can Handle

30, 40, 60, 80-meshSieving

Sieving Machine

-

Freeze Dryer

SUS, Capacity: 1,000 L, Can be heated and cooled, Degree of vacuum: 10 Torr

Drying

Tumble Dryer

-

Emulsifier

Scale: 300 L

As shown to the right, a small-scale (50 L) emulsifier can also be used.

Emulsification

Emulsifier

Contact

Contact

Feel free to contact us.

Inquiry form Oryza Oil & Fat

Chemical’s Licenses and Certifications

Oryza Oil & Fat

Chemical’s Licenses and Certifications

- ISO 22000

- ISO 22716

- Raw Material GMP Certification from The Japanese Institute for Health Food Standards (JIHFS)

- Aichi Quality Company

- Halal Certification

- Manufacturing of edible oils and fats

- Manufacturing of medical and pharmaceutical products

- Manufacturing of food additives

- Manufacturing of refreshing beverages

- Manufacturing of feed